Sound Absorption

In Lab –Sound Absorption

Alfa Acoustics provides testing of acoustic material testing in an Impedance tube as well as Reverberation chamber. We extensive expertise in design and optimization of acoustic materials, we provide acoustic testing solutions to our Customers meeting stringent requirements of acoustic market.

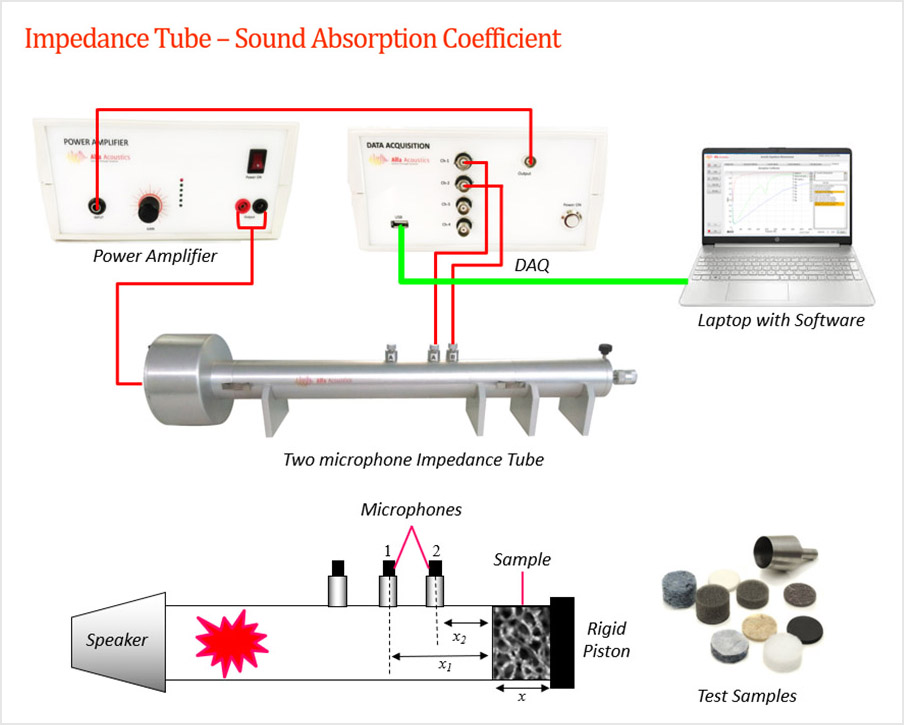

Two Microphone Impedance Tube

It is the quickest and cost saving test method to measure sound absorption coefficient of acoustic materials. Using this method, one can rank number of materials available in-house for their acoustic performance. Being its quickest method, it saves lot of time and cost involved in large size sample testing. Once ranked, only top ranked acoustic samples can only be tested for actual Reverberation room testing.

Alfa Acoustics provides an impedance tube testing along with optimization and new acoustic material development services to its Customers.

The Two microphone testing is conducted as per ISO 10534-2, ASTM E1050, JIS A1405-2 test standards. Along with sound absorption measurement, this method also provides surface impedance and reflection coefficient which are very important in advanced research like Biot parameter characterization.

The surface properties can be easily used for inverse characterization of acoustic samples to get porosity, airflow resistivity, tortuosity, viscous and thermal length.

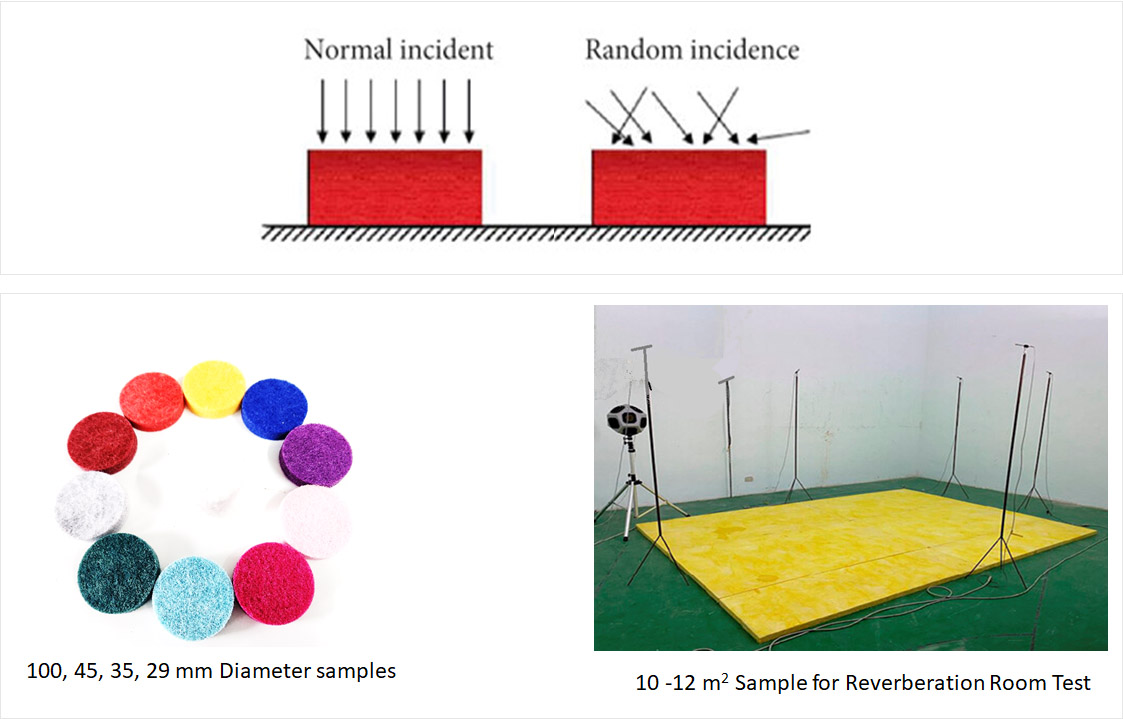

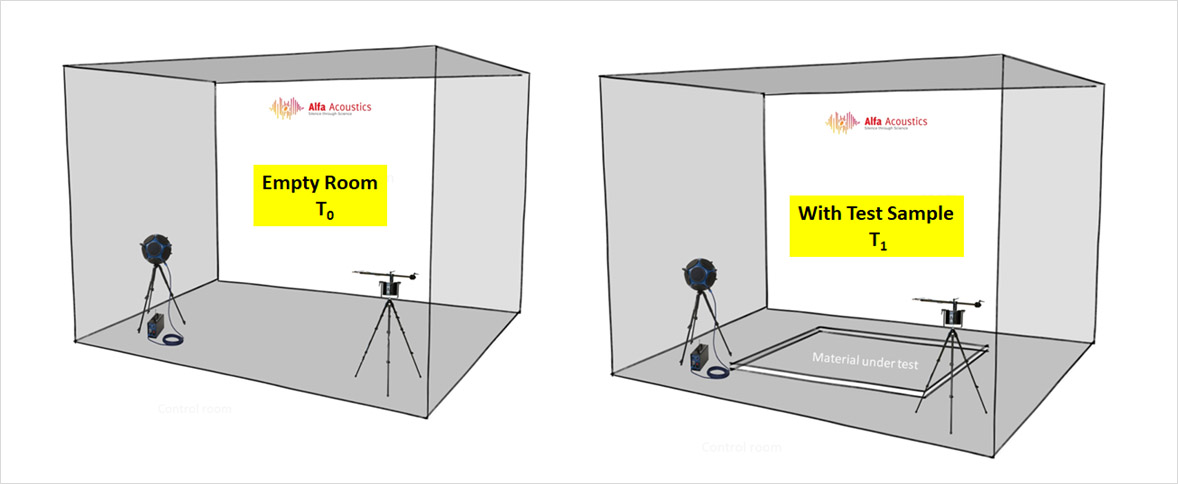

Alfa Acoustics in the only company in the world, in which we have different diameter tubes readily available sound absorption testing. We have 100 mm, 45 mm, 35 mm & 29 mm.

The transfer-function method according to ISO 10534-2 / ASTM E1050 illustrates the possibility of determining the frequency-dependent absorption coefficient quickly with only one measurement. When installing the sound-absorbing material in the impedance tube, various installation options are available that should all lead, in theory, to the same measurement results. However, the diameter of the specimen, the way the specimen is installed, the method of cutting the specimen and therefore also the experience of the person cutting the specimen, will affect the result of the absorption coefficient determined.

The foam material used for these investigations is supplied as sheet material. Instructions on how to produce/cut test specimens are missing from the standard. The finished circular specimens are then inserted into the specimen holder of the impedance tube and can be measured. Three test specimens were produced in each case, one of each with a slight oversize and undersize respectively. This enables a statistical evaluation of the tests.

Acoustic Test Sample–Placement in Impedance Tube

Applications for Impedance Tube

- testing of material characteristics and verifying material compliance before implementing the materials in the assemblies

- design of acoustic comfort in aircraft, helicopters, ships, yachts and vehicle interiors by selecting the optimal acoustic treatments and noise barriers

- research and development of noise control products by benchmarking competitive products

- research jobs for students and universities

- validating and calibrating theoretical computational methods such as acoustic modelling

Sound Absorption Measurement – Acoustic Materials

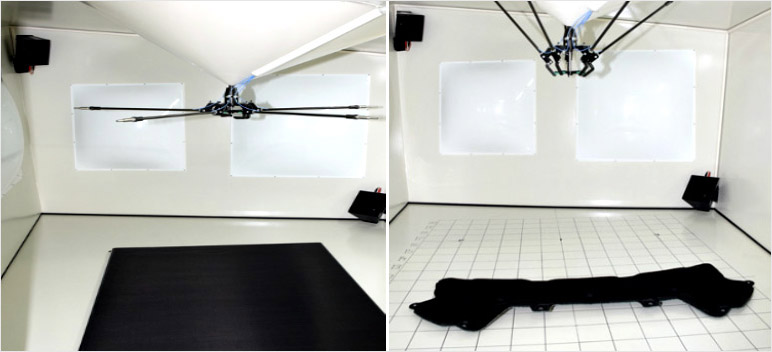

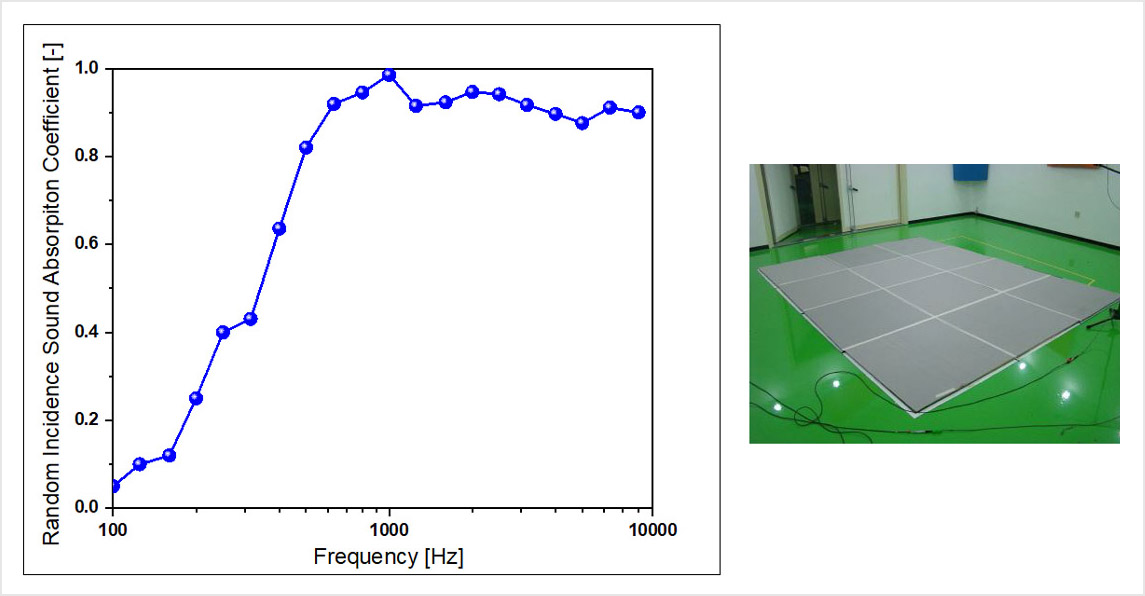

Sound Absorption Coefficient – Reverberation Room Testing

Alfa Acoustics also provides sound absorption measurement in a Reverberation room. The basic difference in between an impedance and a Reverberation room testing is

- Impedance Tube - Normal Incidence with small size sample and later one is

- Reverberation Room - Random Incidence with bigger size sample.

The reverberation room is employed for measuring the reverberation time, and SACs are measured in the reverberation room according to ASTM-C423 and ISO 354. Due to the restriction of the cut-off frequency, the volume of the reverberation room should not be smaller than 150m3. If the volume of the reverberation room is larger than 500 m3, the SAC of the higher frequency band cannot be measured correctly due to the air’s sound absorption phenomenon.

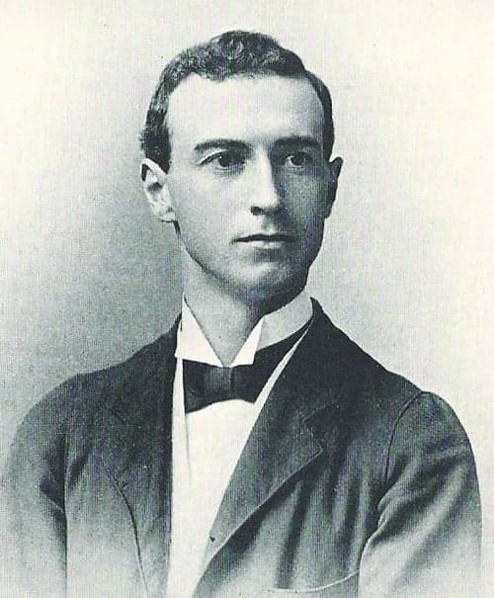

During the testing of a sample, Reverberation time of the empty room is measured first by using an omni-directional sound source. The sound source kept on for 20 sec and then it is switched off to start the measurement. The Reverberation time T60 is evaluated using actual T20 or T30 measurements.

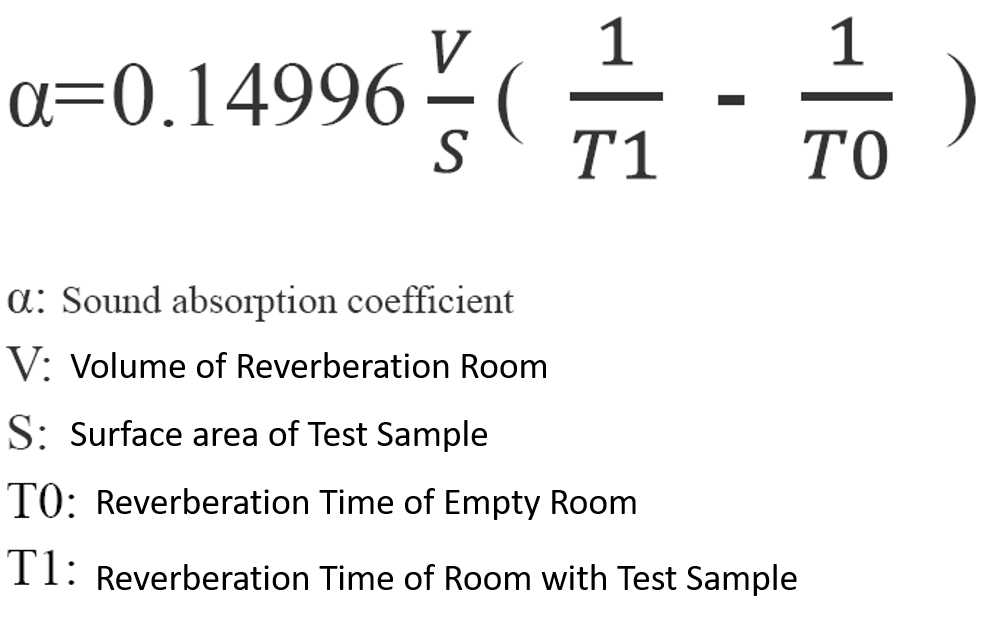

Once this is over, the test sample is placed inside the Reverberation room as per ASTM E795 mounting conditions. After sample mounting, again the same process of T60 measurement is repeated. Once T60 of empty room and with test sample are ready, random incidence sound absorption coefficient is calculated using a Sabine’s formula.

Random Incidence Sound Absorption Coefficient

Once this random incidence sound absorption is calculated, NRC- Noise Reduction Coefficient and SAA- Sound Absorption Average are calculated.

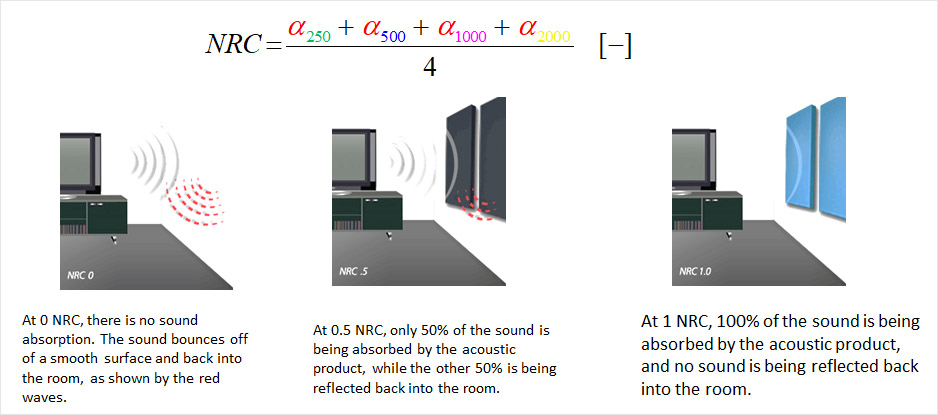

Noise Reduction Coefficient – NRC

- The Noise Reduction Coefficient (NRC) is a single number rating starting from 0.0 - 1.0.

- It describes the average sound absorption performance of a material.

NRC is being replaced by the Sound Absorption Average (SAA), which is described in the standard version 1999 and later versions of the ASTM C423 standard

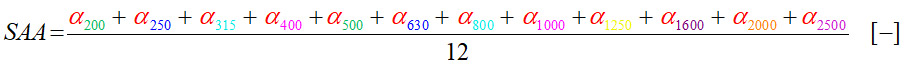

Sound Absorption Average (SAA)

- The SAA is a single-number rating of sound absorption properties of a material identical to NRC.

- SAA averages more points over a slightly larger range, the SAA can be a better indicator of low frequency sound absorption performance.

- It is calculated as per ASTM C423

Sabins : Sabin is a unit of measurement for sound absorption. It is used to describe the amount of sound energy that is absorbed by a room's interior.

It is defined as sound absorption provided by one square meter sample of a perfectly sound absorbing material. It is generally used to showcase acoustic performance of baffles, clouds, islands, acoustic lights and other three-dimensional sound absorbers placed or suspended inside rooms.

Why the Absorption Coefficient will greater than 1.0 at some Frequencies.

When we testing Automotive Acoustic Insulation materials in Alpha Cabin. In theory, the sound absorption coefficient is close to 1.0. But in actual testing, the Absorption Coefficient will greater than 1.0 in some Frequency. What causes the sound absorption coefficient to be more than 1.0?

There are 2 reasons for the Alpha Cabin sound absorption coefficient to be greater than 1.0

Reason 1. The actual samples size is big than 1.2 m2, It makes T1 (Reverberation time after samples in Alpha Cabin) reduce. This caused (1/T1 - 1/T0) increased. The S and V is always the same. So it makes the Absorption Coefficient is greater than 1.0

Reason 2. Border effect, we put the testing samples in Alpha Cabin, All four sizes of the sample will be sealed in Alpha Cabin. But after sealing process, the sound in Alpha Cabin will still enter the sample from the samples four sides. It also make T1 (Reverberation time after samples in Alpha Cabin) reduce.

So for some materials with good sound absorption, the sound absorption coefficient in Alpha Cabin testing will be greater than 1.0 at some frequencies.