Software

Software

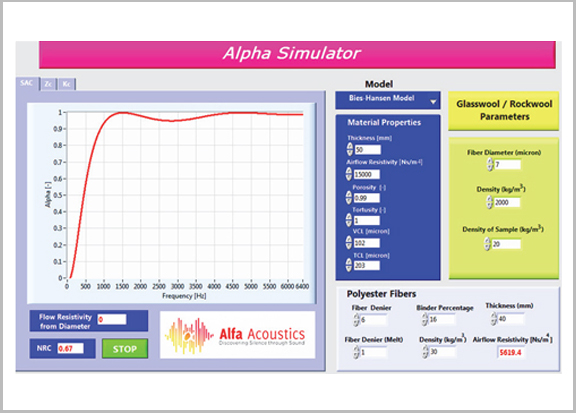

- Simulation Software for predicting acoustic performance of acoustic materials in terms of absorption and transmission loss

- Inverse software for evaluating intrinsic parameters of acoustic materials which are required for CAE simulation

- Sound absorption Optimization software

- Customized software for predicting sound absorption values (NRC) from fiber denier or airflow resistivity

Alfa Acoustics α - Sim is a simulation software for predicting acoustic performance of acoustic materials used in Automotive or Architectural Acoustics. It is a simple user-friendly software which is based upon mathematical modelling of acoustic materials and uses physical parameters like Airflow resistivity – single parameter or with other number of parameters like porosity, tortuosity and characteristics lengths. It can also take fiber denier as an input to predict sound absorption and sound transmission loss of fibrous materials like Glass wool or Mineral wool or Polyester felts.

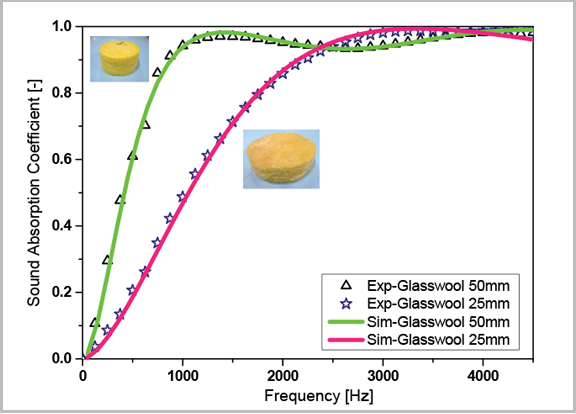

Simulation of Sound Absorption for Glass wool – Double Thickness

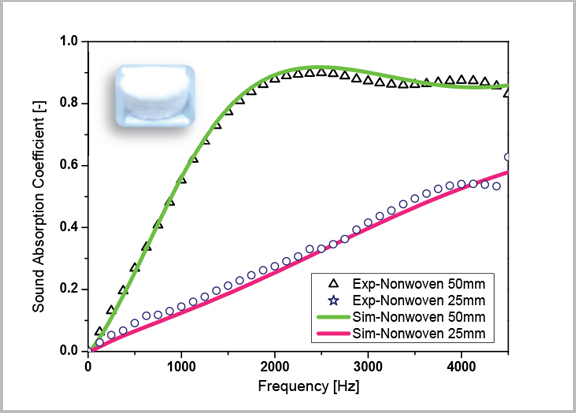

Simulation of Sound Absorption for Polyester Felt – Double Thickness

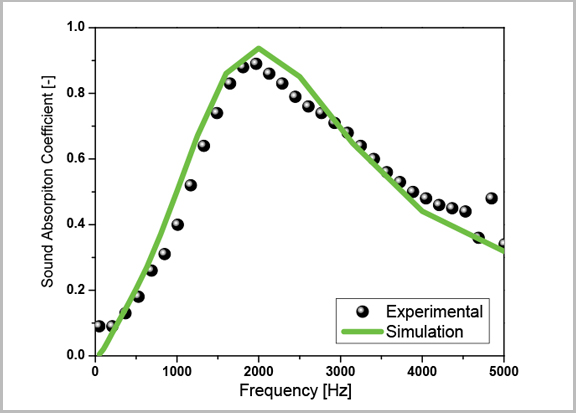

Simulation of Sound Absorption for Composite Materials

- Useful for Manufacturers, Suppliers, Architects, Engineers

- Low Cost and Easy to use

- Gives NRC and STC values within seconds

- Prediction for Normal as well as Random Incidence

- Useful for In-house quality control

- Uses measured flow resistivity or fiber denier as an input

- Predicts effects of Scrim, foils and films also

- Possible to predict acoustic performance for different thicknesses without manufacturing actual material

- Saves time and Cost

- Foam - open cell, metallic, chipped foam, etc.

- Fiber - glass wool, glass fiber, felt, cotton, fabrics, etc.

- Resistive Screens, Fabrics, Perforated Plates, Films, Foils, etc.

- Viscoelastic and sound deadeners

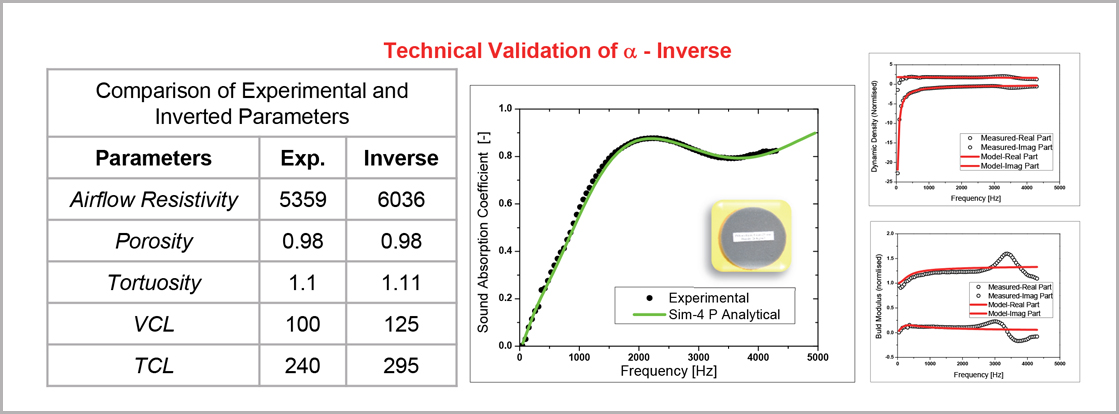

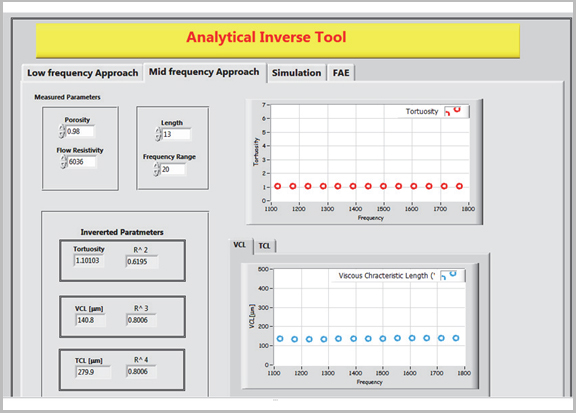

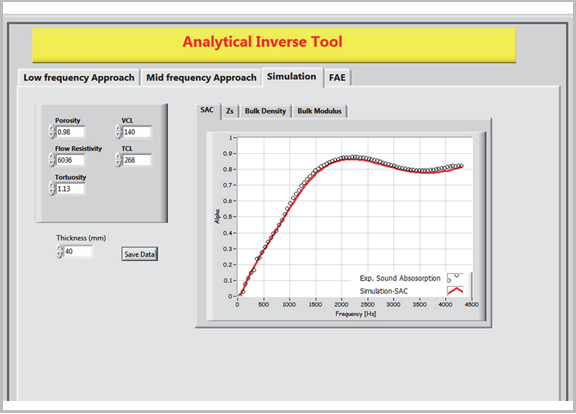

α- Inverse : Physical Parameters of Acoustic Materials

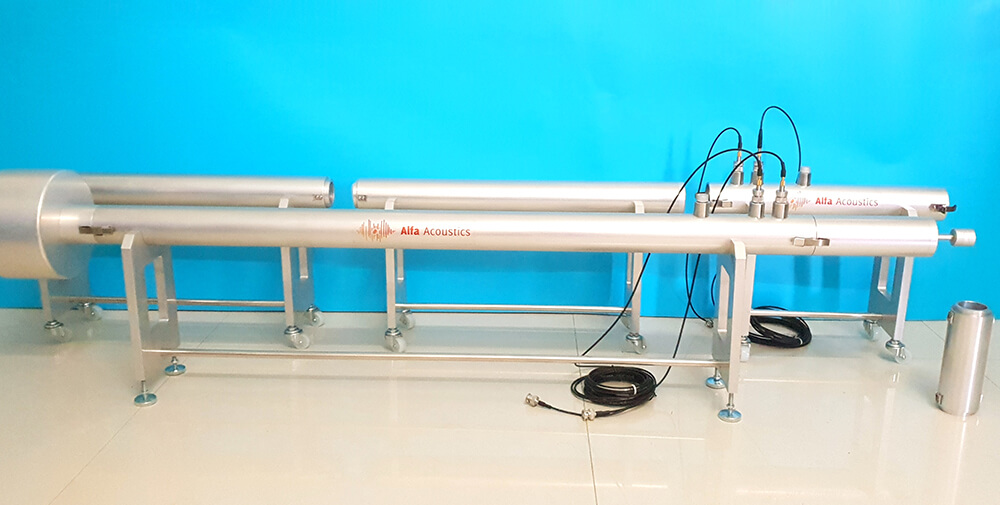

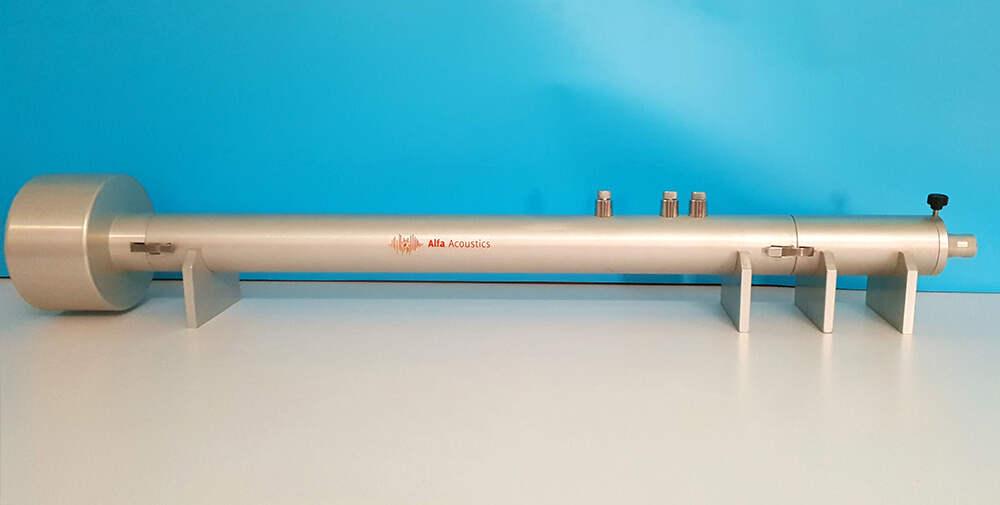

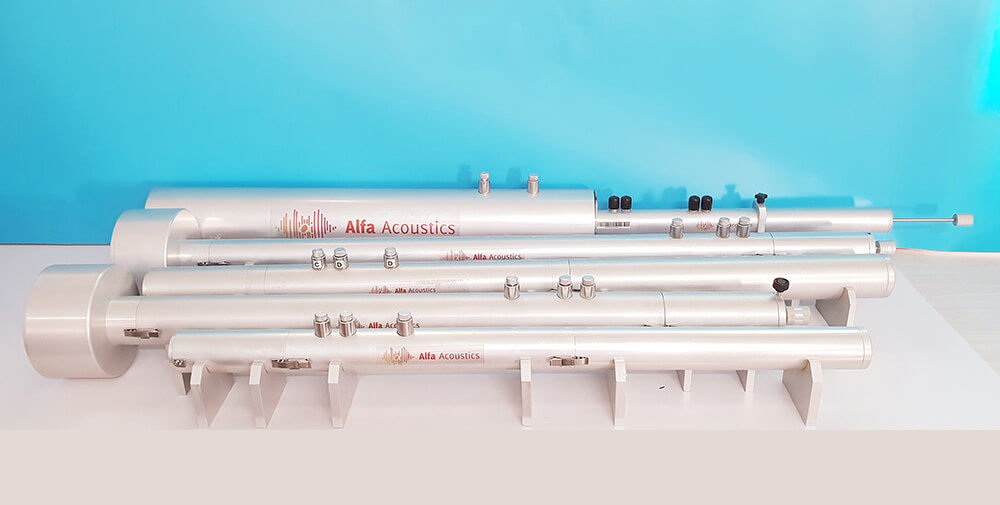

α - Inverse is a simple and powerful tool to get intrinsic parameters of acoustic materials. Acoustic performance of sound absorbing porous materials is governed by its intrinsic parameters (Biot Parameters). These parameters are very important in material - component - product level simulation process. α - Inverse provides a simplest and easiest way to get these Biot parameters with desired accuracy. It works with ASTM E1050 / ASTM E2611 sound absorption and transmission loss measurement systems and only requires porosity as a measured parameter

- Airflow Resistivity

- Tortuosity

- Viscous Characteristic Length (VCL)

- Thermal Characteristic Length (TCL)

- Simulation –During simulation in softwares like α -sim, NOVA, VAOne, Virtual Lab, SEAM, etc.

- Foam - open cell, metallic, chipped foam, etc.

- Fiber - glass wool, glass fiber, felt, cotton, fabrics, etc.

- Errors are below than 5% compared to measurement

- Quick and simple

- Saves huge cost and time