Products

Porosity Rig

Alfa Acoustics - Porosity test rig is based on Boyle’s law. The principle is to reduce the volume of an enclosure where a material sample is placed. While doing so, the pressure will increase in the enclosure compared to the atmospheric pressure. This increase of pressure depends on the volume of the enclosure and the volume accessible to the air inside the porous medium. By measuring the pressure increase it is possible to determine the open porosity of the material.

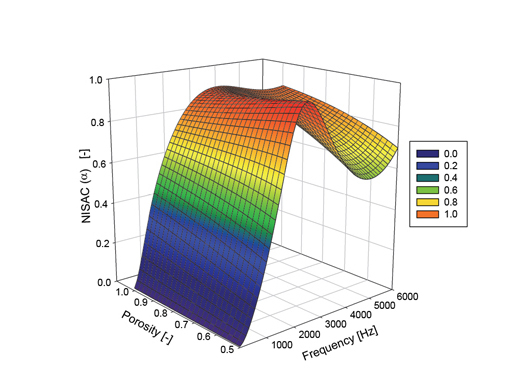

Porosity is one of the important parameter for sound absorbing acoustic materials (Biot Parameter). The sound absorption coefficient is mostly governed by porosity of sound absorbing materials.

Quality Control of Acoustic Materials –Highly useful for quality control of acoustic materials during manufacturing process.

Simulation –Important parameter for simulation in softwares like VAOne, Virtual Lab, SEAM, etc.

- Open-cell foams

- Glass wool, Mineral wool

- Cellular, Granular materials, fills

- Felts, Fibers

- Concretes, Open Porous Asphalts

Effect of Porosity on Sound Absorption

| Porosity Test Rig | |

|---|---|

| Overall Dimensions | 0.45 x 0.55 x 1.2 m (L x B x H) |

| Sample Diameter | 100 mm |

| Sample Thickness | 5-100 mm |

| Airflow Source | Pneumatic Piston |

| Porosity Range | 0.3 - 0.99 [-] |

| Applications | Foams, Fibers,Felts, Natural Sound absorbing materials, etc |

- Low Cost and Perfect for Quality Control

Airflow Resistivity Rig

Alfa Acoustics - Airflow Resistivity test rig is designed as per ASTM C522 / ISO 9053 standards. This method requires simultaneous measurement of air pressure difference across the open cell acoustic sample with respect to air volume velocity. The test rig consists ofa specially designed transparent sample holder for holding acoustic test samples. A pressure pump is used to suck the air through the sample and the rate of airflow through the sampleis controlled by a pressure regulator.

Quality Control of Acoustic Materials - Highly useful for quality control of acoustic materials during manufacturing process.

Simulation –Important parameter for simulation in softwares like VAOne, Virtual Lab, SEAM, etc.

- Open-cell foams

- Glass wool, Mineral wool

- Cellular, Granular materials, fills

- Felts, Fibers

- Concretes, Open Porous Asphalts

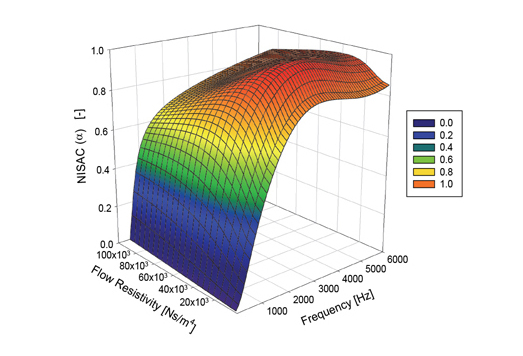

Effect of Airflow Resistivity on Sound Absorption

| Airflow Resistivity Rig | |

|---|---|

| Overall Dimensions | 0.45 x 0.55 x 1.2 m (L x B x H) |

| Airflow Source | Pressure Pump |

| Standards | ASTM C522 / ISO 9053 |

| Airflow Resistivity Range | 500 - 1000000 Ns/m4 |

| Applications | Dash Insulator, Headliner, Hood Insulator, Trim Parts, Resistive Scrims |

- Designed as per National / International Standards

- Low Cost and Perfect for Quality Control

Email - alfa@alfaacoustics.com; info@alfaacoustics.com, www.alfaacoustics.com

Download